Plant and Machinery

WHAT OUR CUSTOMERS THINK OF US!

Our company has been using INGECO Gearboxes since last 7 years and their quality and service is outstanding. Ingeco has wide range of gear boxes, which is very useful to our non standard plants,we have used Ingeco K20 gear box, which is performing very good without any service problems. We can rely on the products and supply our plants fitted with their Gearboxes. Overall good quality, ontime delivery and strong service backup.

Mr Venkat Ramana( Puzzolana Machinery Fabricators )

INGECO products are extremely reliable and our experience with the company has always been positive. They have kept pace with new developments and with the evolution in the industry supplying high performance speed reducers with greater reliability. It has always been a pleasure to do business with INGECO and we look forward to many years of quality products and services and strong business relations.

Mr Mahesh Jagetiya( V.K Enterprise, Rajkot )

Great Product and easy installation. The entire INGECO team is very supportive throughout the whole process of buying until the gearbox installation. Even after our plant started, they were just a phone call away for any queries or concerns regarding the maintenance of the gearbox. Their product has replaced costly foreign gearboxes and is giving extraordinary service. Keep up the good work INGECO team.

Vasudev Earthmovers( Sayla, Gujarat - Having 4 Nos 400 TPH Crushing plants )

We commend the efforts and dedication shown by Ingeco team in supplying Gearboxes to our company. Their prices are fair and meet the delivery commitments. They do great work and I wish them all the best.

Mr Hiten Shah( Relcon InfraProjects Limited- Mumbai )

We endorse INGECO Products as a single source supplier for various gearboxes they carry. Their reliable products, professional approach and exceptional customer service support are unparalleled in the industry. Thank you for your great efforts in completing and dispatching specially developed gears and pinions for our plant. We hope the same for all our future requirements.

Rhino Machines( Gujarat )

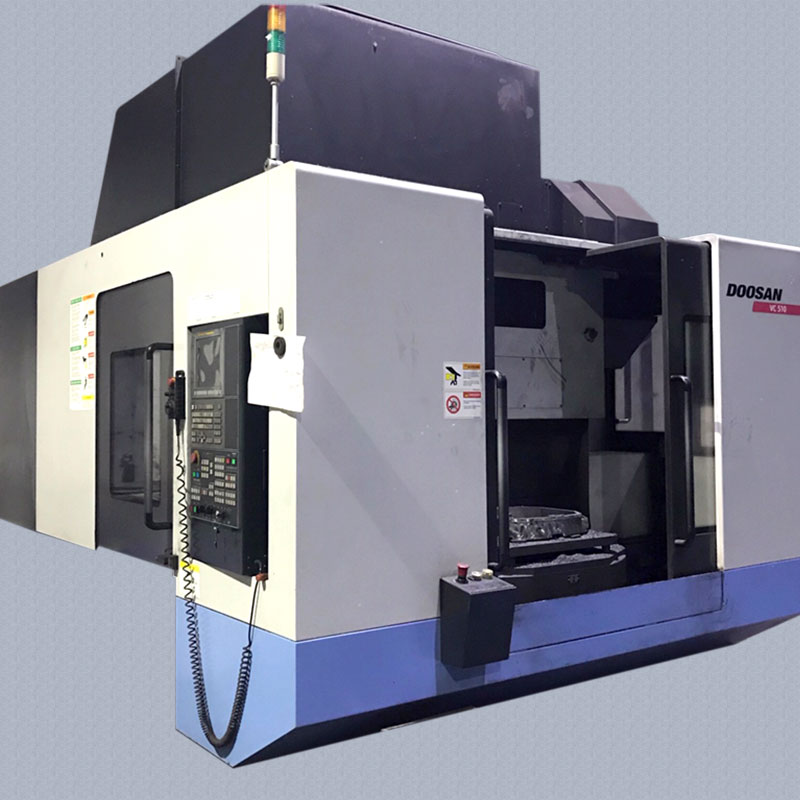

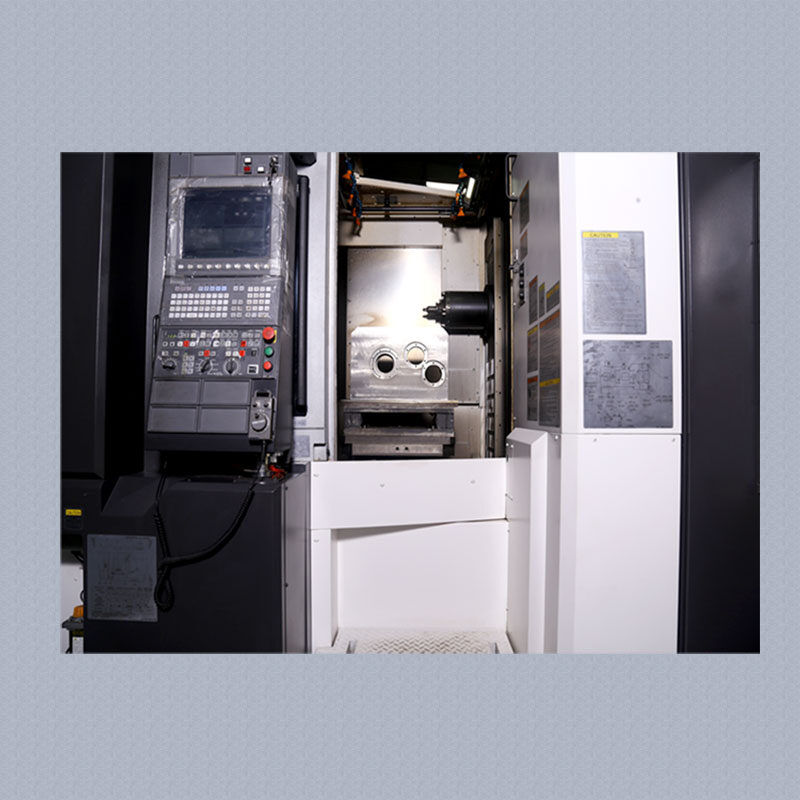

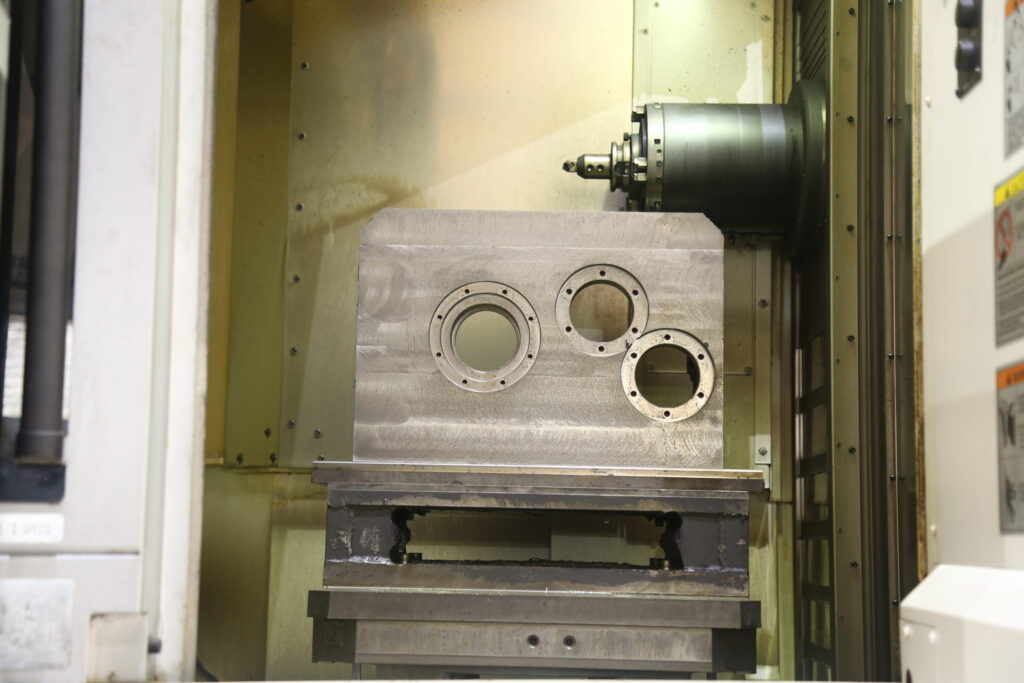

INGECO have been associated for the past 35 years for supplying the Gearboxes for our plants and Road making machines and their delivery has been impeccable and the quality is at par to international standards. Their products are an import substitute for lot of our applications. They have a good plant set-up and latest Gear related machinery.

Mr Kishor Patel( Ammann India )